Vision Systems

Our Team

The Vision System Group was founded in 2001 to meet the growing demand and need for vision system integration and turn-key vision systems in manufacturing and automation. Our team has been involved in various applications with many Tier – 1 entities to provide robust solutions for error proofing and robot guidance. The group has worked across the board from the automotive industry to packaging. Systems have been installed all over the U.S. in addition to various locations throughout the globe such as Mexico and Europe. Due to the groups breadth of talent and experience they are very familiar with many of the standards, processes, and practices put in place and used throughout the industry today.

Integration Offering

Providing a complete turnkey solution ensures unparalleled quality of product and service. We ensure our clients realize the cost advantages through the implementation of the following..

- Application feasibility reporting

- Custom application software & operator interface

- Lighting and optical path design

- PLC Modifications

- Plant schedule (broadcast) interface

- Error Proofing interface via AIS

- Network communications for remote access and monitoring

Power Train

⦁ Data Matrix Code Reading on Torque Converters, and shafts (Laser Etch)

⦁ Data Matrix Code Reading on Blocks, Heads, Cranks (Pin Stamp)

⦁ Piston Assembly & 360°Ring Quality Error Proofing

⦁ Needle Bearing Inspection

⦁ Thrust Washer Verification

⦁ Engine Component Error Proofing (End of Line)

⦁ Plug Wire, Coil pack, and PCV Valve Error Proofing

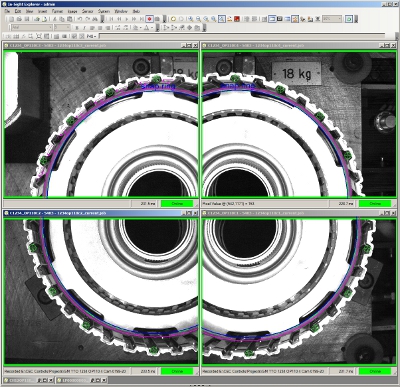

⦁ Stator Assembly Error Proofing

⦁ 6-F Valve Body Verification

⦁ Brake Assembly Verification

⦁ Flywheel Orientation and Rundown Verification

⦁ Saturn

⦁ Exhaust Manifold Error Proofing

⦁ ZF

⦁ Rocker Arm Assembly Error Proofing

⦁ Gear Stack Verification

⦁ Snap Ring Seated Verification

⦁ Engine Timing Verification

Body and Trim

⦁ Body Side Load

⦁ Body Side Match

⦁ Trans Oil Cooler Error Proofing

⦁ D-Pillar Stiffener Error Proofing

⦁ Catalytic Converter Verification

⦁ Shifter Position Verification

⦁ Body Color Verification

⦁ Hummer Console Component Error Proofing

⦁ TRS Position Verification

⦁ Instrument Panel Frame Clip Verification

⦁ Brake Caliper Error Proofing

⦁ 2WD VS 4WD Hub Error Proofing

⦁ Roof Rack Error Proofing

⦁ Urethane Bead Inspection

⦁ Bumper Style Error Proofing

Robotic Guidance

⦁ SUV Inner Aperture Left and Right 3-D Auto Racking

⦁ SUV Outer Aperture Left and Right 3-D Auto Racking

Assembly Verification

Console Component

⦁The vision system confirms that the console has been assembled correctly.

⦁It has three cameras performing 14 different checks as the part rotates on a turntable.

Thrust Washer Verification

⦁ The thrust washer verification system ensures that the thrust washers are present during manufacturing of the planetary gear.

⦁ The presence of the washer is first detected by measuring the distance between the top of the thrust washer and the top of the gear.

Shifter Position

⦁ The system is used to confirm that the gear shift actuator is in the correct position prior to being mated to the transmission.

⦁ This is a good example of a Go /No Go application. (originally)

⦁ The lighting is a standard flood light that shines through the drivers side window. The camera looks through the passenger side window.

⦁ Flexibility: T-Bird shifter feature was added a year after the original installation.

⦁ Turn-Key

Bolt and Clip Verify

⦁ The system is used to detect the presence and proper installation of 42 different bolts, clips, and nuts.

⦁ Two Cognex color cameras are used

⦁ Each camera is mounted on an ABB Robot.

Part Identification

⦁ Locate Body Panel

⦁ Evaluate Hole Pattern to Identify Body Side Style

⦁ Compare to Production Schedule

Error Proofing

Bumper Style

⦁ The vision will verify that the correct bumper is installed on the vehicle.

⦁ The style select is provided by photo-eyes looking at the chasse.

⦁ A disused vision system from the old T-Bird line will be reconfigured and deployed for this application.

⦁ No broadcast interface is required

Catalytic Converter

⦁ This system is used to verify that the catalytic converter installed on the vehicle matches the plant build schedule.

⦁ The different converter types have unique labels.

⦁ Installed as mono cameras

⦁ Ford added additional converter types, so we upgraded to color cameras.