Mistake Proofing

CEC Controls has globally deployed Mistake Proofing solutions in automotive and manufacturing for 22+ years.

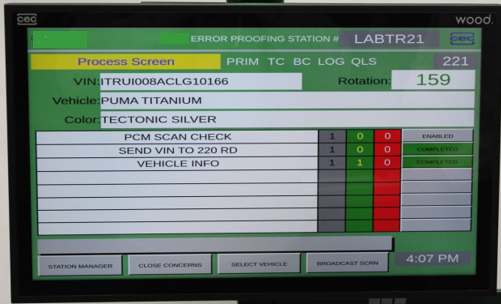

In Station Process Control

- Operator HMI for feedback

- Ensures fasteners are secured

- Assists operators in picking the correct part

- Logs incomplete processes to Quality system

- Standard interface to DC tooling

- Standard interface for process equipment

- Torque Tool Monitoring

- Part Positioning & Verification via Vision Systems

Part Verification

⦁ Pick Light Systems /Scanning Part Code

⦁ Annunciate the proper parts that are required for a vehicle / part assembly within a station.

⦁ Verify that the operator has removed the parts from the bins to meet the requirements of that workstation.

⦁ Scan a barcode to verify the part number matches the required part number.

Car / Part Tracking

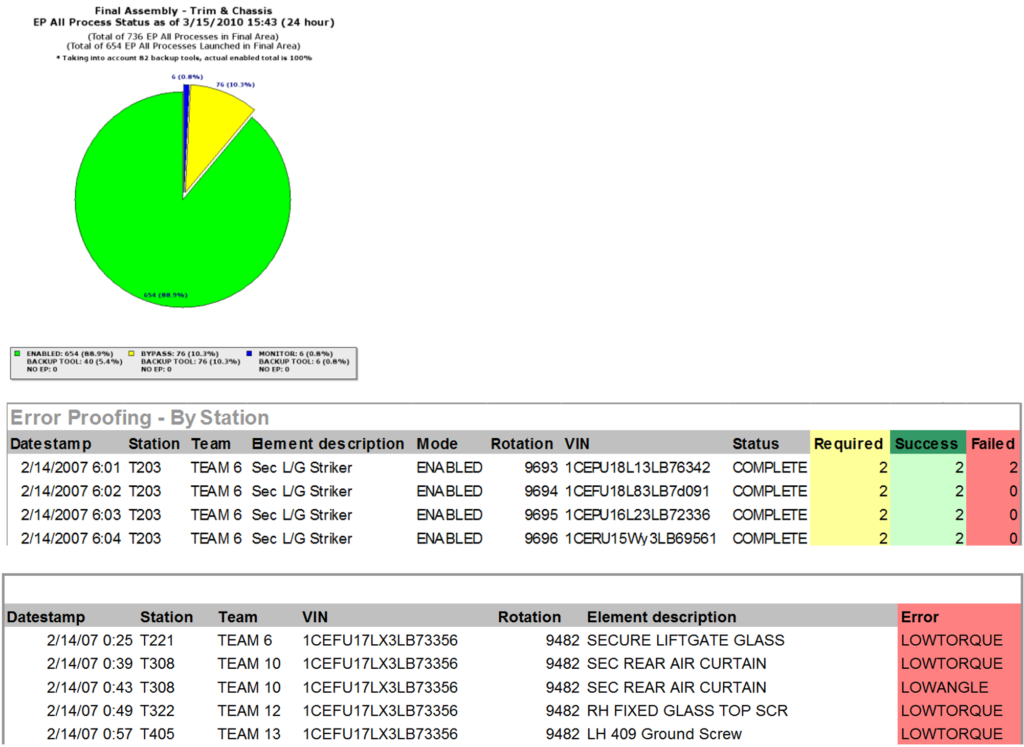

- Web-based HTML5

- Real-Time Tracking

- Real-Time Status

Reporting

- Easy System Configuration through web pages

- Process Status by Vehicle

- Process Status by Station

- Stations Configuraiton Matrix

Working Toward Client Solutions

Our team is able to provide solutions for all types of applications. While we do have customizable hardware/software solutions available for utilization by our clients, we are also able to use off the shelf technology.

Expected Steps for Mistake Proofing implementation include:

- Data Collection of Client Requirements

- Site Survey of existing System/Process

- Development of proposed solution and commercial offering for review with client (typically 2 weeks post site survey)

- Deployment of Solution and training for client

- Available Support from CEC post implementation

Call our team today to discuss how we can help design, implement or improve your Mistake Proofing process.